Scintilla Ltd.

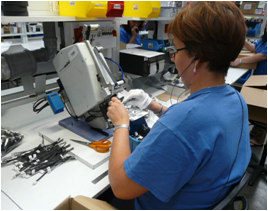

Our company is located in Jászberény (Eastern Hungary), on Ipartelep Street. We started our operations in 1996, as a privately owned Hungarian company. We produce electromechanical parts and internal cables (cable assemblies, connectors, switches, and electric fittings). Our clients are primarily multinational companies based in Hungary and Europe, operating in a wide range of industries: automotive, industrial electronics, telecommunications, and domestic appliances.

We have more than two decades of production experience in the areas of cable confectioning, internal cable production, and electronic assembly, offering a high level of service to our Clients. In recent years we have been placing great emphasis on technical development and capacity expansion, which resulted in the steady expansion of our clientele. Our goal is to serve our Clients flexibly and precisely and provide them with products of excellent quality. To achieve this goal, we implemented SAP, the integrated company management system several years ago. Thanks to our stable IT background, we can provide to our Clients:

We achieve these through a logistics system optimised on the basis of demand, while maintaining an optimal level of raw material and finished product stocks. We possess the most modern and fully automated Komax (Gamma, Alpha) machines, with electric controls and a built-in monitoring system. To achieve excellent quality, we use the methods of TQM (Total Quality Management). Our company operates an IATF 16949 quality control system. The cornerstone of our business philosophy is to serve our Clients quickly and efficiently. With regard to continuous development, we carry out our activities according to the PDCA principle. During production processes, we aim to prevent errors using the POKA-YOKE method, in line with our zero-tolerance strategy.

We achieve these through a logistics system optimised on the basis of demand, while maintaining an optimal level of raw material and finished product stocks. We possess the most modern and fully automated Komax (Gamma, Alpha) machines, with electric controls and a built-in monitoring system. To achieve excellent quality, we use the methods of TQM (Total Quality Management). Our company operates an IATF 16949 quality control system. The cornerstone of our business philosophy is to serve our Clients quickly and efficiently. With regard to continuous development, we carry out our activities according to the PDCA principle. During production processes, we aim to prevent errors using the POKA-YOKE method, in line with our zero-tolerance strategy.

LEAN methodology

At the beginning of 2013 we began applying the Japanese method for enhancing accuracy and efficiency in production, in order to perfect our operations further. We use the LEAN approach both in production and during preparatory activities. The implementation of the 5S system and the use of MUDA (waste) searches and the TPM system (rapid setup changes) allow us to meet the expectations of our Clients at an even higher level and provide immediate solutions to unexpected market situations. In addition, we place particular emphasis on standardisation and the use of Milkrun methods to ensure that raw materials and finished products reach their destination as accurately and quickly as possible.

At the beginning of 2013 we began applying the Japanese method for enhancing accuracy and efficiency in production, in order to perfect our operations further. We use the LEAN approach both in production and during preparatory activities. The implementation of the 5S system and the use of MUDA (waste) searches and the TPM system (rapid setup changes) allow us to meet the expectations of our Clients at an even higher level and provide immediate solutions to unexpected market situations. In addition, we place particular emphasis on standardisation and the use of Milkrun methods to ensure that raw materials and finished products reach their destination as accurately and quickly as possible.

We use an internal system of indicators to measure the efficiency of the company’s processes. These indicators allow us to assess customer satisfaction, the correctness of our decisions, and our development. As a result, our Clients obtain a partner that is constantly developing, increasing its efficiency, and striving for market excellence.